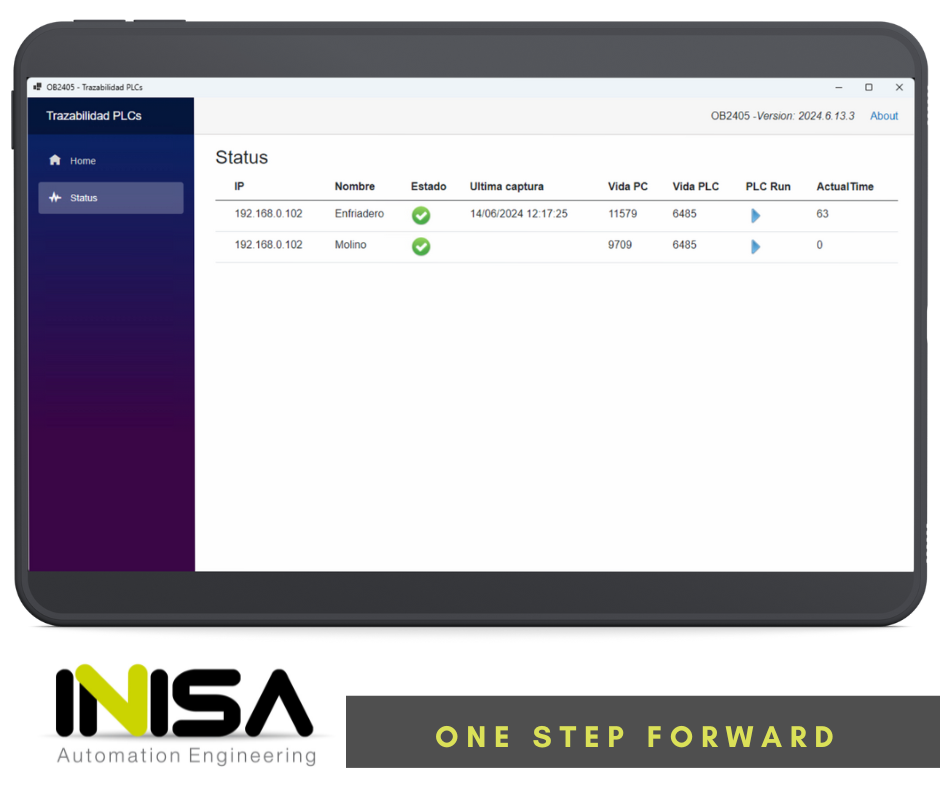

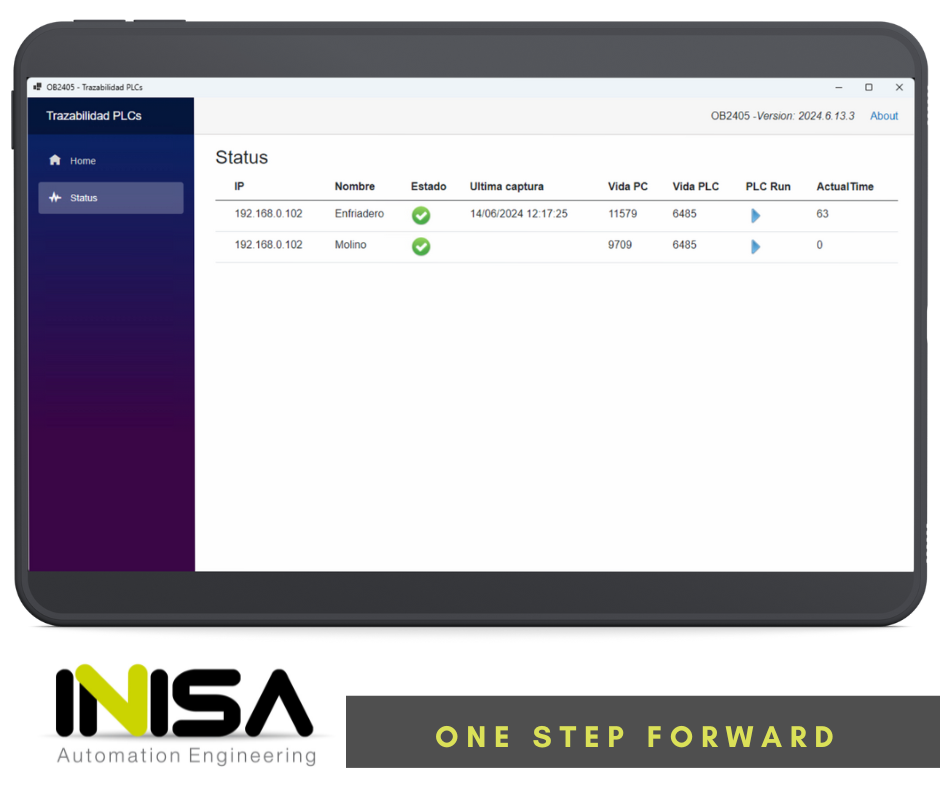

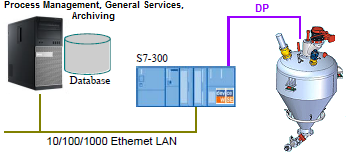

Data Logging from 2 S7-300 PLCs to File Server

Objetives: Our client, an iron, steel and metal foundry, requests our collaboration in exporting data from several S7-300 PLCs to be saved in CSV on

Objetives: Our client, an iron, steel and metal foundry, requests our collaboration in exporting data from several S7-300 PLCs to be saved in CSV on

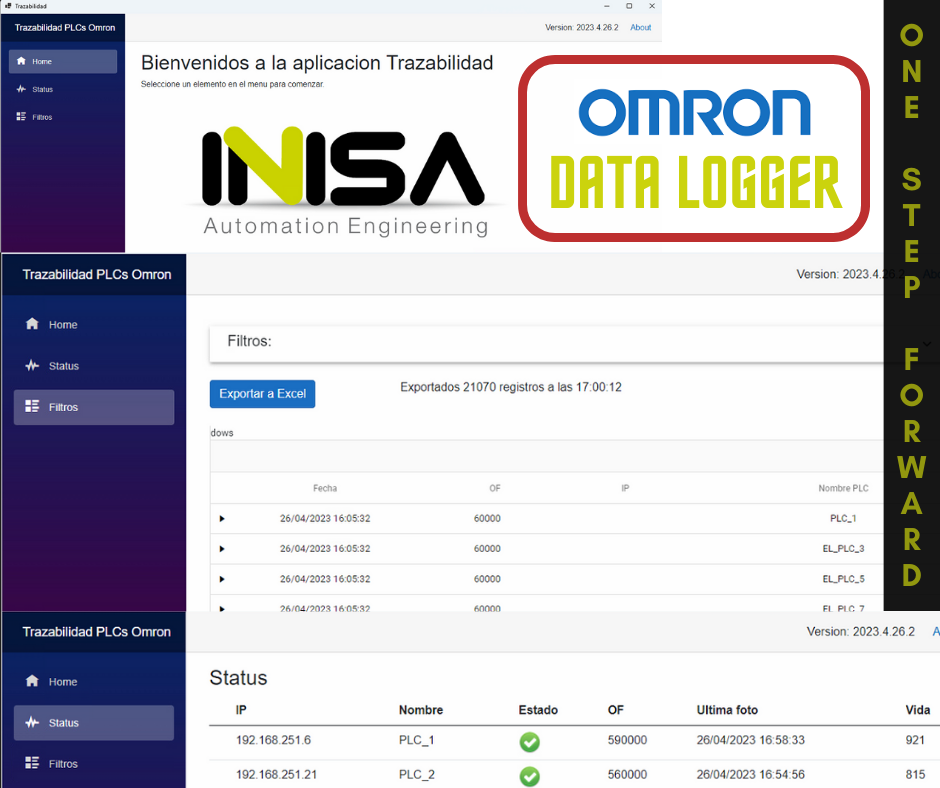

INISA develops a communication software for Omron PLCs network, capable of using FINS protocol, the most common in these PLCs. The program, developed on platform VBnet, runs on a Fanless PC, without a monitor or keyboard (Does as a data logger) and allows the capture of data from various processes of various PLCs, managed by their occurrence events.

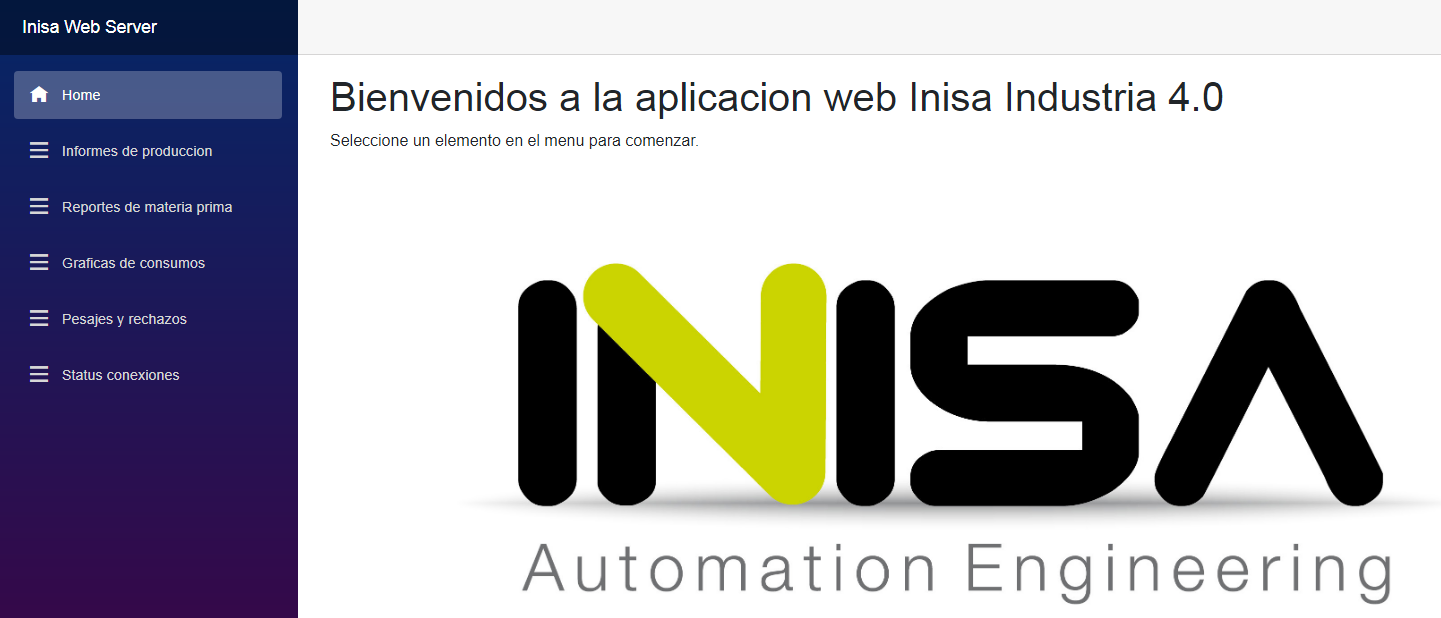

To create a digital platform (Web Server) that provides a personalized solution to companies and thus have the information thy consider relevant to their processes, accessible at any time, from any place and device ( Anytime / Anywhere / Any Device Concept), segmented for each category of factory staff that should received and analyse it.

Our customer, Capital Goods manufacturer, and in a line that is already installed and in production, wants to register and analyse information relative to energetic consumption, reached pieces production and other plant parameters, that allow future decisions for the optimal exploitation. Both, from the point of view of the line manufacturer (Hours of use of the different sub machines, spare parts management, load percentage respect to the nominal, etc.) as well as the point of view of the production/productivity achieved. All this in order to optimize and offer better installations and services to its customers in the future.

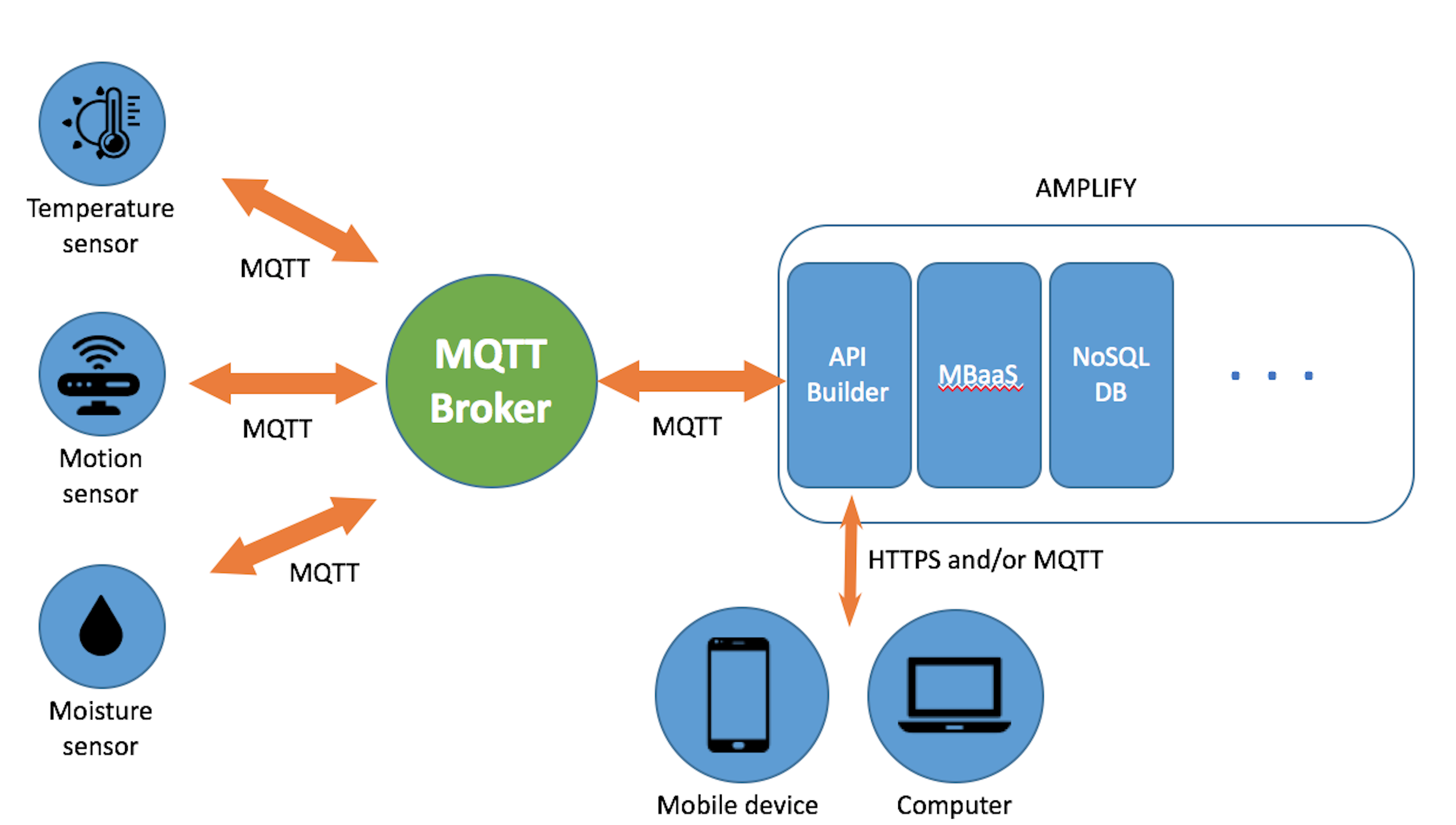

MQTT (Message Queue Telemetry Transport) is a lightweight Machine to Machine (M2M) communication protocol that is used in Industry 4.0 and IoT applications environments. It is an open standard (ISO / IEC PRF 20922) and it is based on the publication-subscription pattern. It works on the top of the TCP/IP stack. Its main objective is to exchange messages between clients and a server (Agent-Broker). Clients can decide for themselves if a message is important to them, depending on the topics to which they have subscribed.

What is needed is to identify the necessary and existing production variables in the plcs already in the plant to be able to access to its variables bidirectionally (reading and writing) using a browser, interacting in this way with their information from higher-level systems.

It is a development of the computer department of INISA, with the operative specifications set by the customer. The maintenance staff of the factory has a common space (SQL Data Base) on which they indicate the working orders that manage the corrective and preventive maintenance actions.

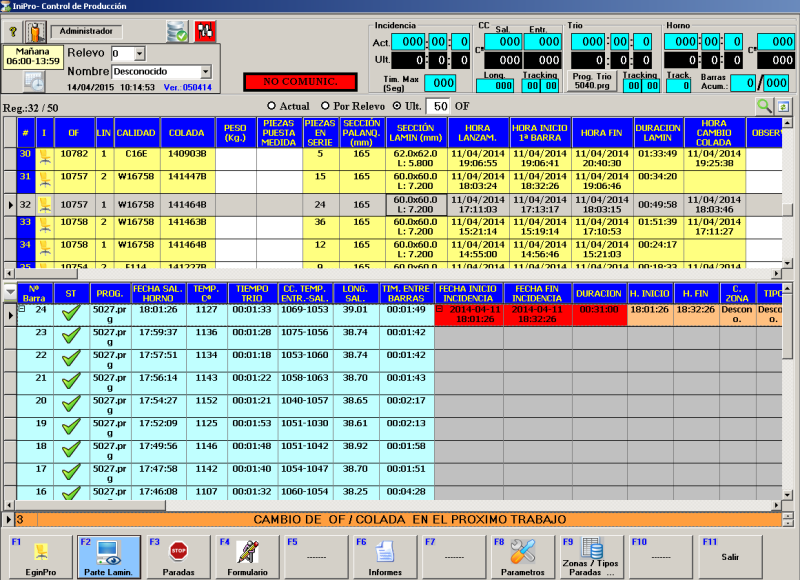

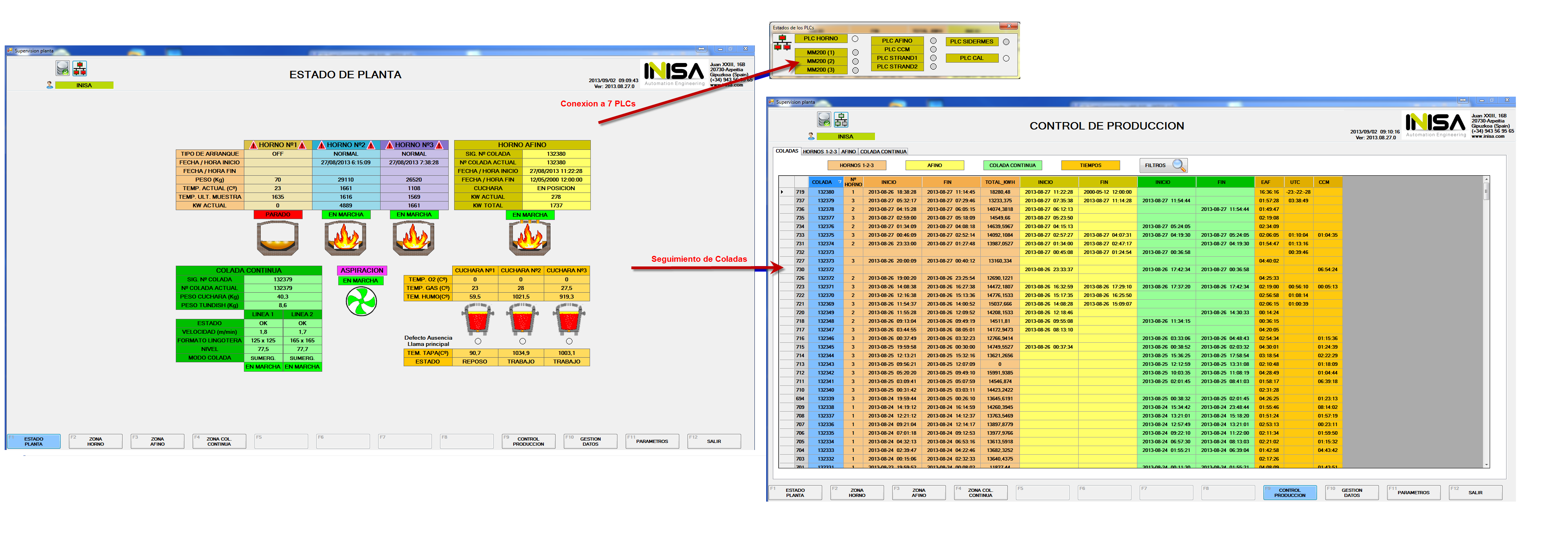

To carry out the tracking and the traceability (SQL DATABASE) at billet level, recording furnace output temperatures, input and output to/from continued boxes, as well as the Inter-billet between each of them.

Fusion furnaces, refining furnaces, continuous casting, refrigeration … processes All of them associated with the castings done in a steel mill and which have to be registered in real time on a Common Data Base for the access from any computer of the plant or from outside…

NECESSITY: To know the data about the additives used in lime and additive injection processes. PROBLEM: The process PLC doesn´t have a communication canal with

Upgrade your PLC / Robot / SCADA, both hardware and software (Increased performance and/or functional improvements, such as the complete redesign of a CFF (flexible manufacturing cell).

Adaptation to machine safety regulations, CE marking, making updates to standards.

Selection and design of technologies that allow us to create projects with our own product, using Industrial communications standards (Modbus, MQTT, Bluetooh, BLE, Wifi, Zigbee), for the most diverse sectors, home automation, Industrial, Automotive, with examples of products in progress.

Industrial Internet of Things. Traceability, events, maintenance, Notifications / Mail production reports, cloud, with PLCs or Things currently in their factories or newly implemented. Use of connectivity protocols between devices, such as MQTT and others.

By means of remote and/or on-site remote assistance, anywhere in the world, which allows improvements, programme changes and fault resolution. Also on implementations of other manufacturers. Our experience in different processes and knowledge of the technologies at your service in the rapid resolution of faults.

Programming and fine-tuning services for industrial robots in a wide range of business sectors. For this purpose, we have a team of programmers experienced in integrating robots from the main manufacturers: KUKA, ABB, FANUC

We offer technical advice to end customers on the purchase, implementation and monitoring of projects. carried out at their facilities by other machinery manufacturers involving automation, we help to define the requirements and specifications of the project, analyse the offers received technologically and economically, and carry out the project management and validation of the installation in production. In other words, achieving the objectives set.

We analyse and look for effective solutions, where “know-how” is important.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

More information about our Cookie Policy