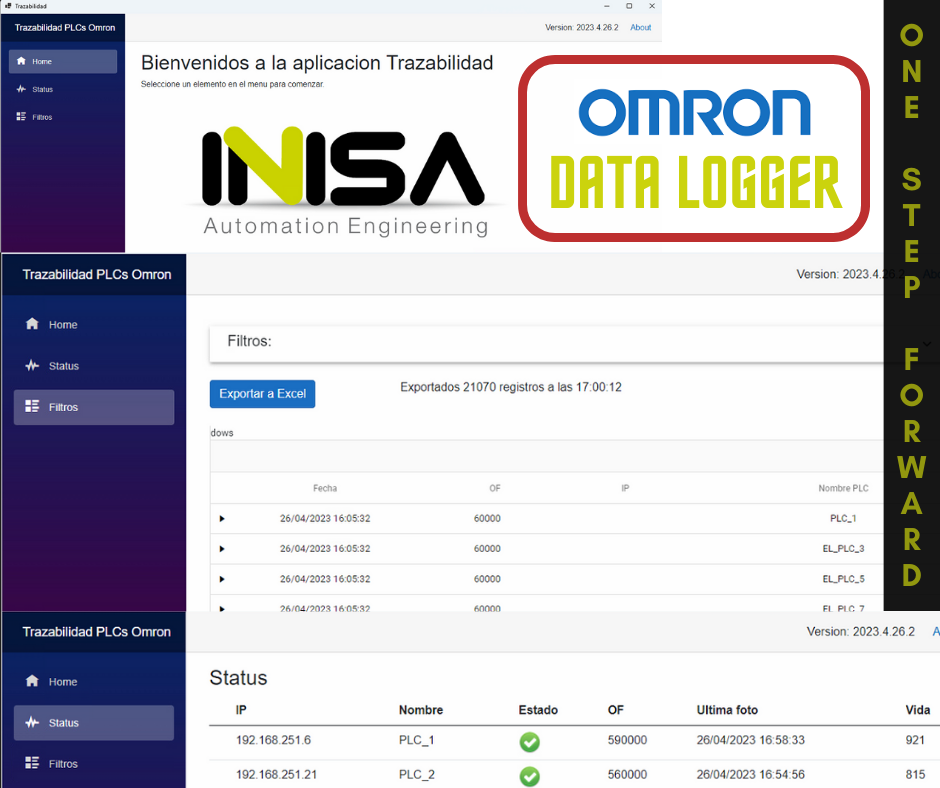

Easy data logger on Omron PLCs network

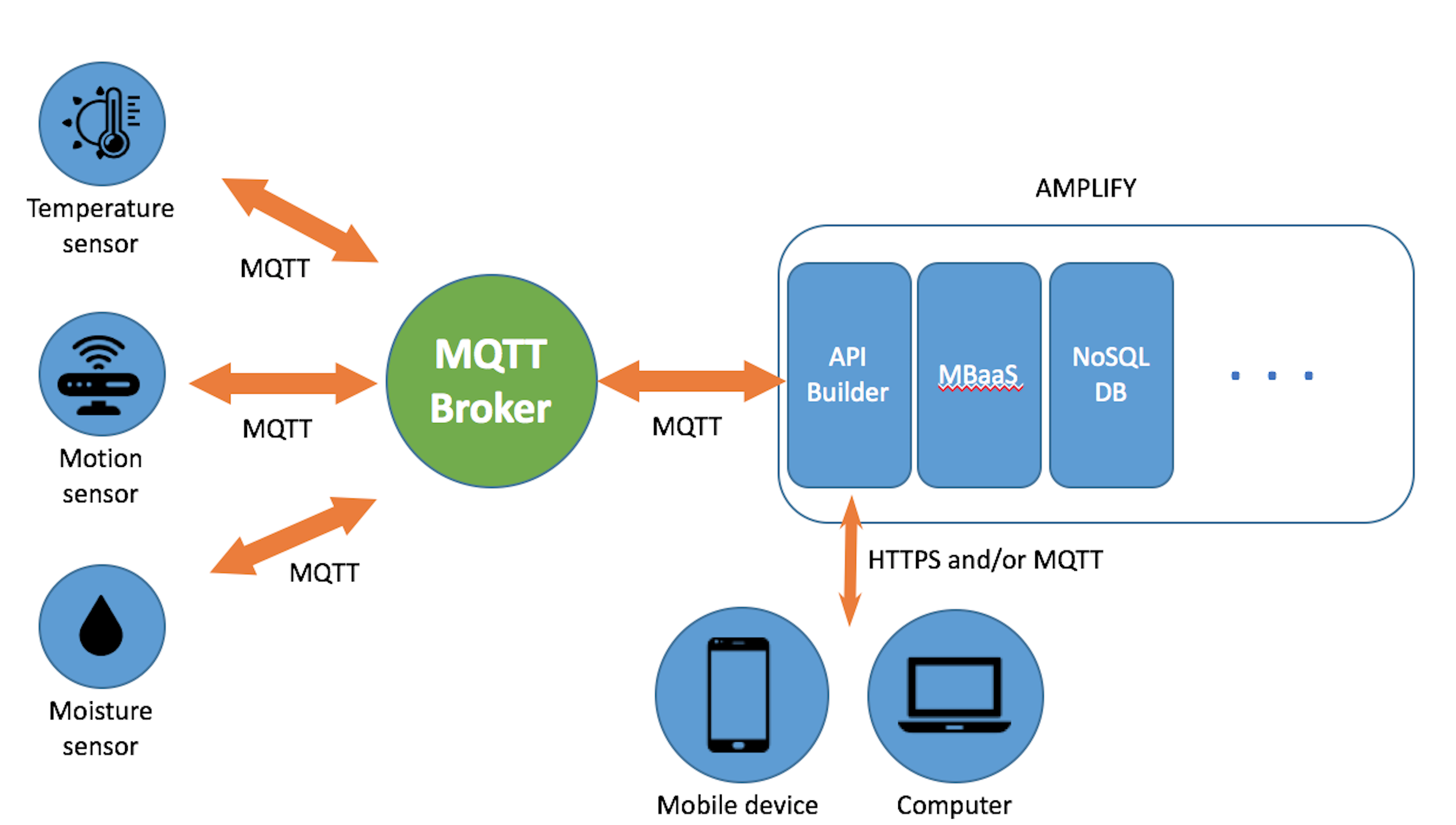

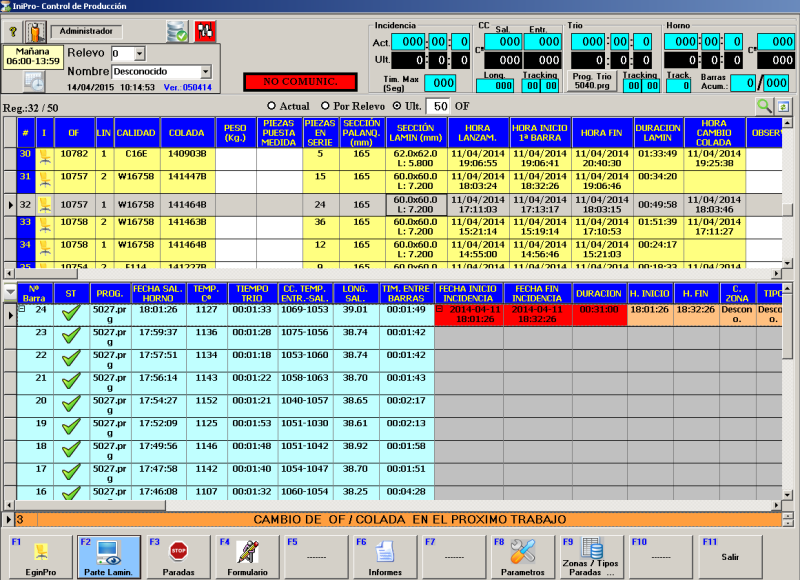

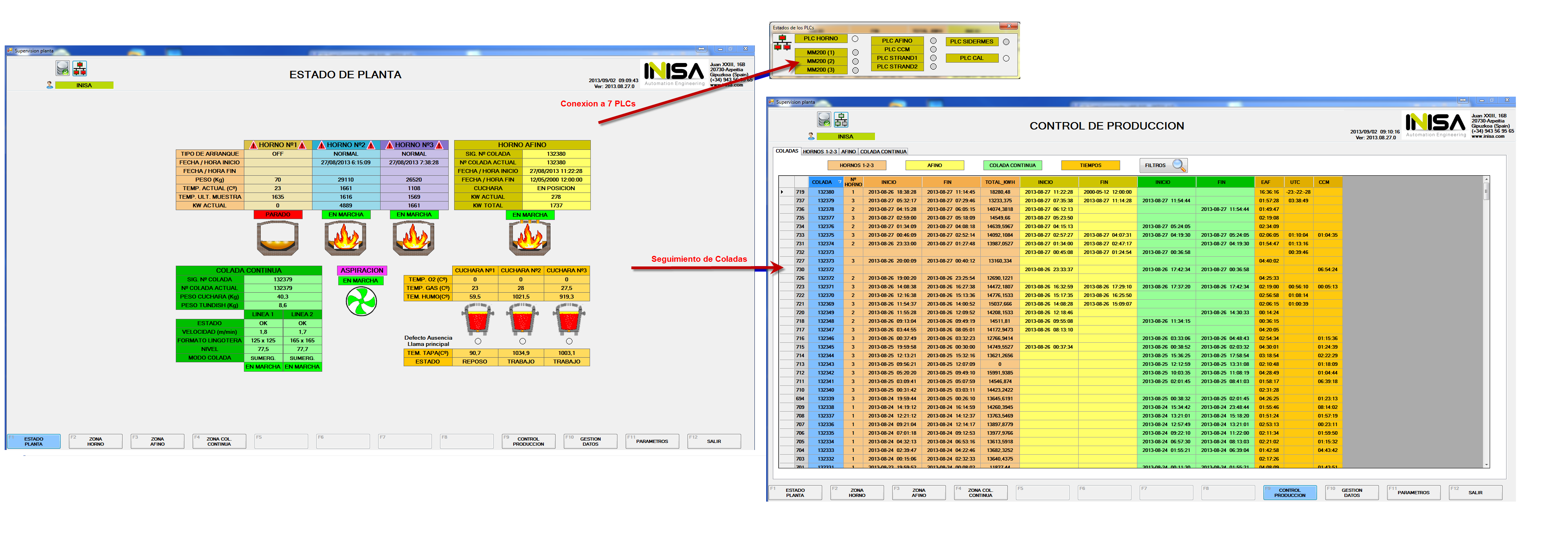

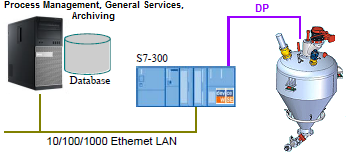

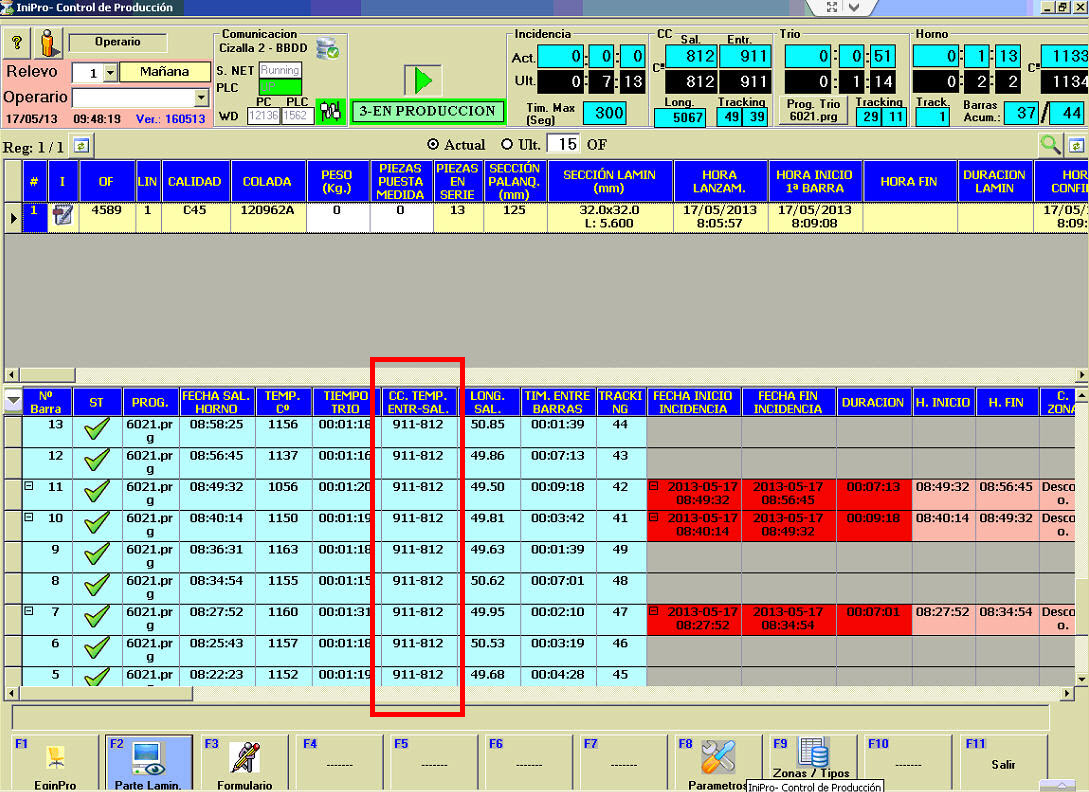

INISA develops a communication software for Omron PLCs network, capable of using FINS protocol, the most common in these PLCs. The program, developed on platform VBnet, runs on a Fanless PC, without a monitor or keyboard (Does as a data logger) and allows the capture of data from various processes of various PLCs, managed by their occurrence events.