Objetives:

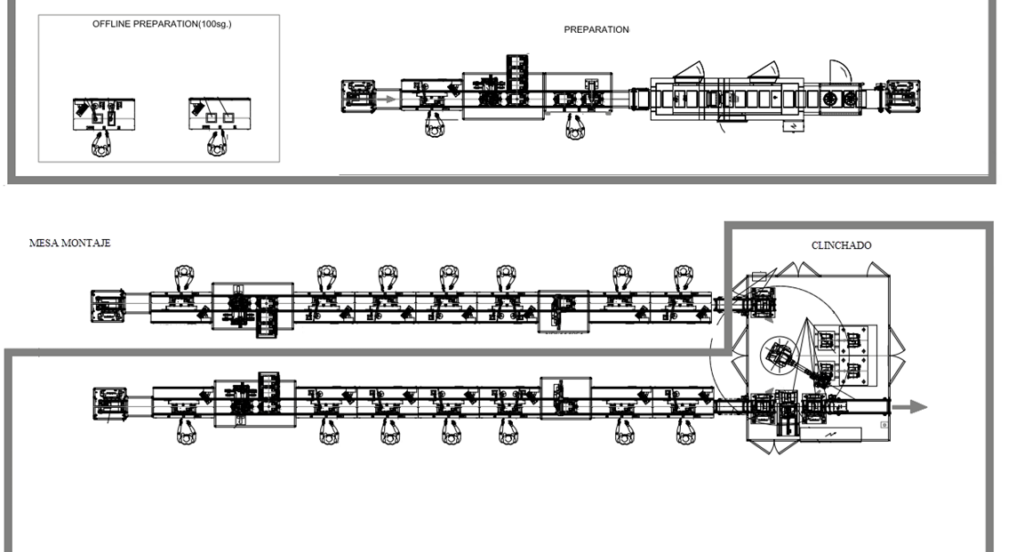

Our client, a manufacturer of automatic lines for the precise insertion of components in the Automotive sector, asks us to collaborate as Engineering in one of its lines for the introduction of electronic boards into a housing, for the electric car/e-mobility market. The lines are made up of various areas, such as preparation, assembly tables and clinching. INISA is in charge of the development of the HMI software in its entirety, including, in addition to the OPC UA communication with the process PLCS and the SCADA for managing the entire line, communication with the end customer’s traceability system that allows knowing all the production process in it.

The Automation has been carried out with OMRON NX120 and NJ501 equipment and computers with a personalized scada made with the .NET platform, which ensures compatibility and long product life.

The line has been tested locally at its facilities (Spain), installed at the destination (Morocco), and our presence at the destination has not been necessary since we have carried it out remotely.

Process:

Preparation area, composed of a manual table, a dispensing machine, a press and a furnace.

Manual assembly table area, each branch (Line) consists of 10 positions, such as a Manual assembly table, a dispensing machine and a welding machine. It has mechanisms for screwing, vision, sensorics and detectors, confirmation, etc.

Clinching is a process that allows two or more metal sheets to be joined together. It is a method where the parts are joined by cold deformation.

Milestones:

The main objective of the application is to guide the operator at all times which operations must be carried out in each position, both in the preparation line and on the assembly and clinching tables.

The SCADA/HMI, in addition to monitoring, also has a model manager and a reference manager with which is possible to generate different profiles. Manages alarms viewer, warnings viewer, initial conditions viewer, manual drive movements, traceability…

After a successful first project already carried out previously for this client, this new project has meant a continuity in the collaboration with him, undoubtedly the result of the satisfaction of the parties in its execution and development.

INISA, your trusted partner in the automation of your manufacturing lines.