Objetive:

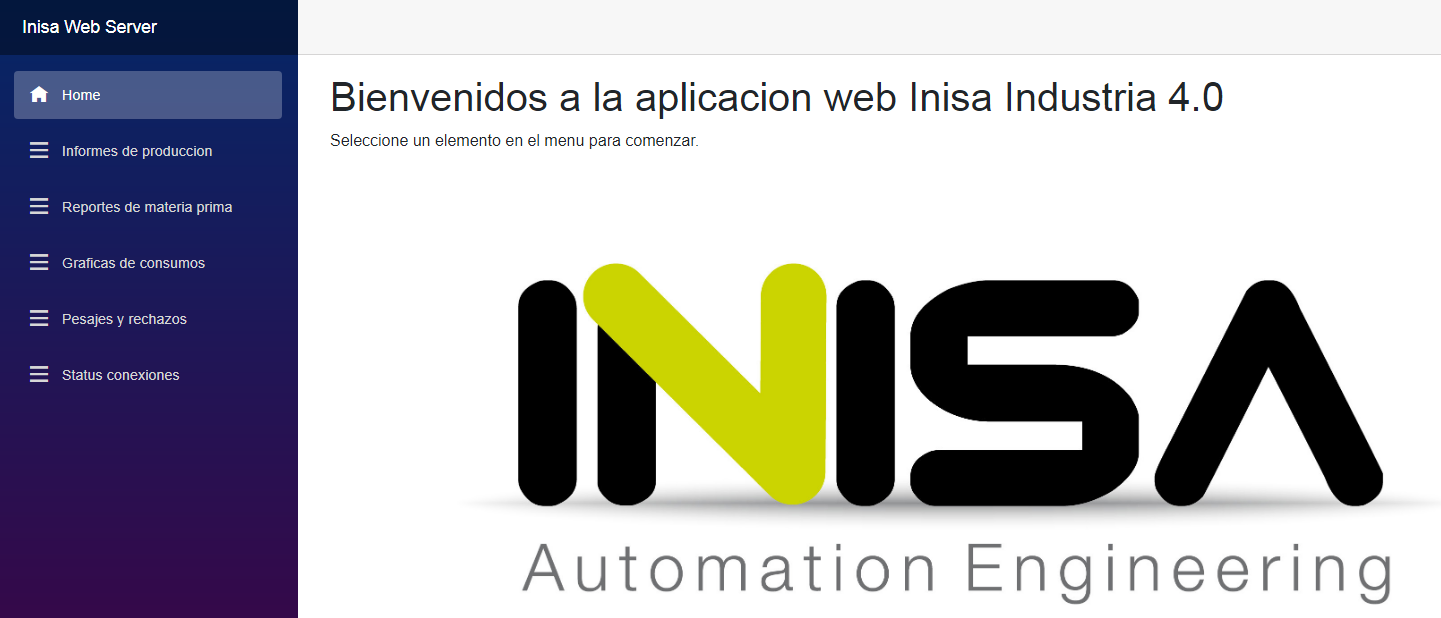

To create a digital platform (Web Server) that provides a personalized solution to companies and thus have the information thy consider relevant to their processes, accessible at any time, from any place and device (Anytime / Anywhere / Any Device Concept), segmented for each category of factory staff that should receive and analyse it.

These functionalities are being used by our clients, providing a great value in making production decisions, managing and improving their processes, by knowing their production and creating events in a 24h/7days scheme.

This is a modular solution, which shares agents’ common services and functionalities (Software programs) between different clients, obtaining important cost reductions in the implementations and in the maintaining and improvements that can be applied in the future.

Customer solution and steps for implementation

The solution includes the recording of production data, the sending of emails with production events, filtered reports of consumption, Plant status (DashBoard), all accessible through a web server, in 2 simple steps:

Company: Identify the information you want to have accessible and the people for whom it would be intended. Establish the necessary reports (Scheduled in a defined and configurable frequency). Define the events that cause mails emissions with alarm events, production carried out, etc. to the recipient persons.

INISA: Study the information sources of the necessary data (PLC, Production signal, etc.) that are in the factory. See the need for implantation of the capture agent and the equipment available in the factory to have the communication. Reserve the structure in PCs / virtual machines / cloud that could be outside the company (Less maintenance) and provide the specific web server solution adapted to the client’s requirements, taking advantage of the common coding for all services (Maintenance of the DB, Mqtt reads, user / role configuration, protection of external access to the server) etc.

We will be happy to study your application for capturing information in the plant. Call us without obligation to provide you with our best solution.

Inisa, your plant information integrator