In INISA, 30 years in the world of industrial process automation has given us the experience of using diverse programing tools form different PLC manufacturers of the market and also the option to follow its all evolution, from the use of serial RS232C cables to the current programming via Ethernet, in addition to the different operating systems used (from MSDOS to Windows10).

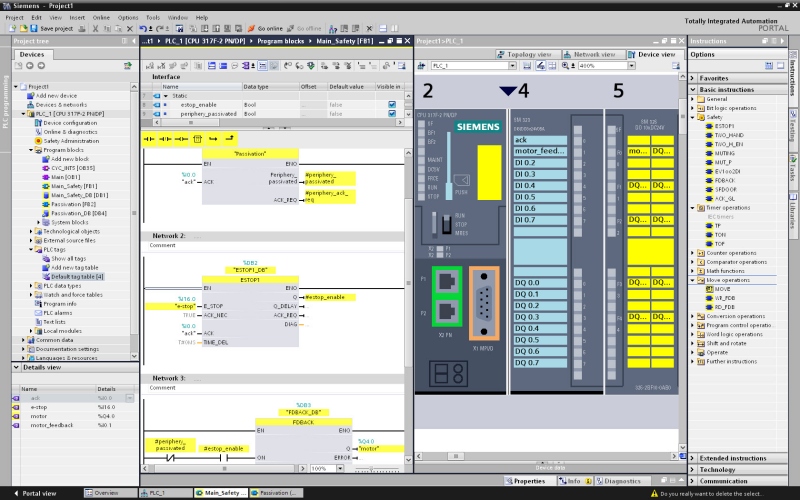

Without doubt, the integration of the different elements of a project, PLC, touch screens, servos, robots, etc. have better application programs ( for example TIA Portal platform) and therefore “all in one” type solutions that make life easier to the automation engineer programmer.

Up to here, the good thing from the view of programming. In parallel, and even more with the actual Industry 4.0 concept, the customers’ needs have changed. From only automate the process, it is going to have greater control in the level of information about it.

In this article we are going to focus in only one aspect of the value chain, provided by INISA to an automation process, and it’s to IMPLEMENT RELIABLE SOLUTIONS, on where the customer use experiences on our facilities, avoid travelling and/or remote assistances because malfunction or defective programming.

To this end, in INISA we set a challenge, TO AUTOMATE THE AUTOMATION.

The last goal of this concept is to develop applications with a standardization that minimizes repetitive tasks on the development of projects, based on:

- Standard distribution of the programing blocks, referring to the different parts of the machine, according to rules.

- Standardization on the data structures, necessary form control. Process variables, parameters, Bits of touch screens, etc.

- Standardization on the management of operations engines (inversion motors, drivers, servos, etc.). They all have a common pattern.

- The design of positioning routines and axis control with closed loop by the PLC (Encoders) and/or position capturing elements.

- Standardization on the development of process grafcets, that adapt to the most of the automation processes

- …

And some advantages:

- The development of big projects in concurrence of several program engineers, assigning different machines to each one.

- To focus on solving the automation process. The devices control and the way of automating is the same.

- The interchangeability or substitution of engineers for the continuity and/or set-up of the projects.

- Easy process simulation on our offices. Reaching the set-up with more proven processes.

- In short, RELIABILITY on automation service, satisfied customer that repeats the automation with us.

Undoubtedly, in automation, with INISA you get more.