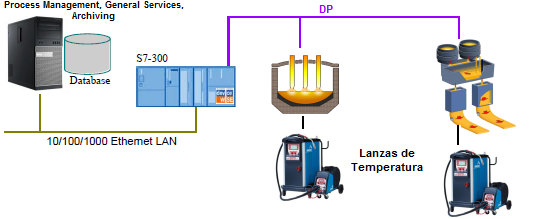

INISA has completed with exit the integration in the production plant Data Base of the data referring to two sample-takers submerged in fusion bouillon, which give casting information as:

-Data and time of the sample done

-Temperature, measured Carbone, calculated Carbone, Aluminium, Oxygen ppms

-Total number of sounding lines used by each furnace

-FIFO Pile of the last 6 samples done

INISA has a communication software module which allows recording the data only when these have changed, don´t using communication buses unnecessarily, so increasing the performance

INISA, Innovation in Automation…