Objetives:

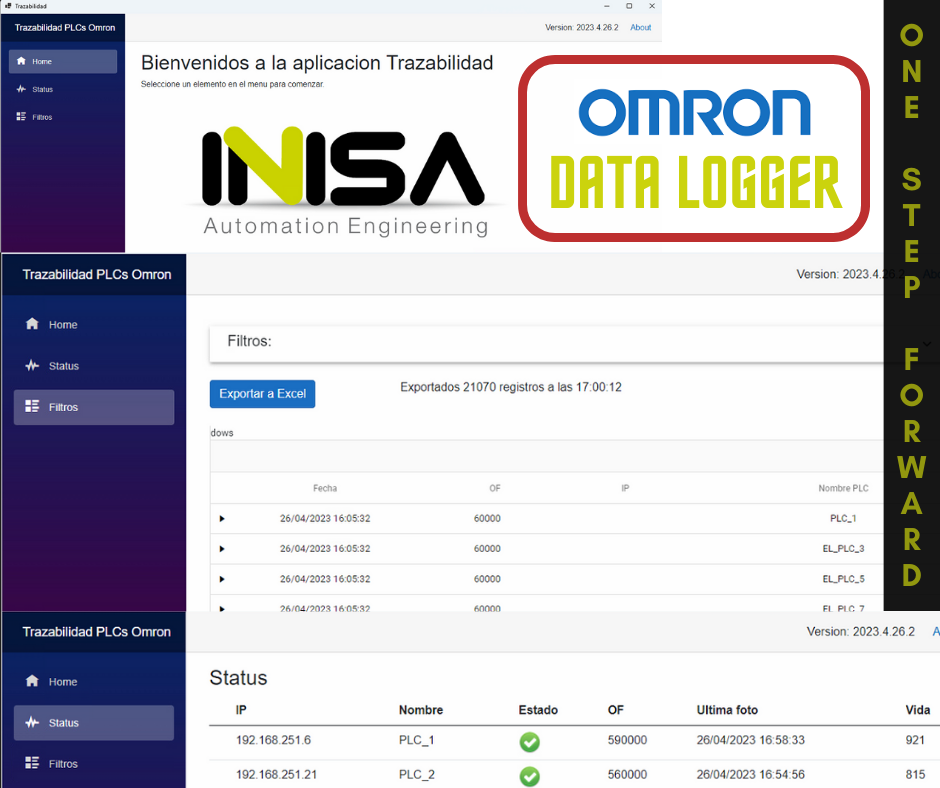

INISA develops a communication software for Omron PLCs network, capable of using FINS protocol, the most common in these PLCs. The program, developed on platform VBnet, runs on a Fanless PC, without a monitor or keyboard (Does as a data logger) and allows the capture of data from various processes of various PLCs, managed by their occurrence events. It is possible in any current factory or facility where these conditions exist:

- Define a configuration with the name and IP address of each PLC in the network, valid later for the generation of reports.

- Define the variables within the PLC that would be read when a/some process event/s occur/s. Currently up to 100 variables per PLC and event (expandable). Each variable is configured by the user to have an associated text that clarifies its meaning.

- It is possible to communicate up to 8 PLCs simultaneously (expandable), with n definable events for each PLC. Several plant installations with the same data logger.

- It can be implemented in any current Omron PLC with FINS protocol. Inisa supplies the customer with the PLC program routines/blocks necessary for event management and intercommunication with the PC datalogger, in operation 24 hours a day.

- Depending on the number of PLCs, variables and events, the frequency of the registered events can be up to 200 milliseconds.

- In the PC, a common database is generated with the information of the variables of each event, of each one of the PLCS. The user has a filter screen to view the data, by manufacturing order ranges, between dates… generating process reports in Excel/pdf. Data can be communicated for traceability to other IT systems, or necessary filters can be added.

Utility:

It is a proven communication solution, which allows data to be recorded in databases with a PC program implementation time and routines added to the PLC of less than one day (For 8 PLCS). It is only necessary to have 100 contiguous variables in the PLC and copy the variables with the process information that you want to record into these. The PLC program is provided by INISA.

It allows issuing process reports to customers who ask us for traceability in the pieces that are produced, with the physical variables that they have had during their manufacture. From the Excel sheet, the user can, using macros and/or Excel scripts, represent graphs, maximum/minimum frequencies, etc. Ability to choose the PLC variables that are necessary, the frequency of events, and the processing of information in Excel. Otherwise, INISA would perform the desired customization.

Cost/Return:

As it is a solution designed for the functionalities described, and since it is largely configurable, the cost return on investment is very fast (< 3 months). It does NOT depend on a particular data collection hardware, a fanless PC with the operating system and software are enough.

INISA, Omron data logger