Objetives:

Our client has asked us to remove part of the INTERBUS hardware from one of its current manufacturing lines. Some of the configured and installed elements were frequently failing due to obsolescence, causing downtime and loss of productivity.

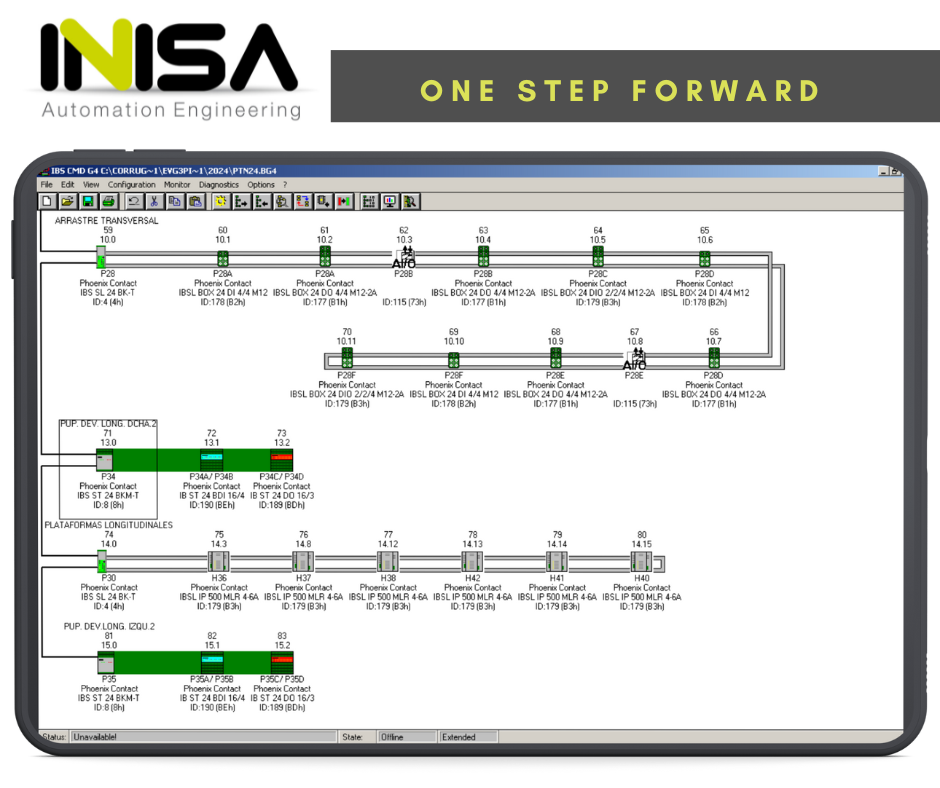

With a PLC and installation of around 30 years, and after collecting the current project in operation, the current configuration is analysed and modified for its correct operation. It is a SIEMENS S5 PLC (still working…) and an INTERBUS master card that generates the network and exchanges information with the CPU.

Used tools:

- Siemens: S5. 115U CPU 943B.

- Phoenix Contact: Interbus IBS S5 DSC/I-T.

- Software: IBS CMD SWT G4 y STEP5.

Process:

During the unpacking process, several pieces of hardware were left over that collected different PLC inputs. The wiring is re-adjusted avoiding said hardware and its participation in the project is analysed for its safe disposal.

Once the changes have been made by the Electronics department, the commissioning process begins with a minimum downtime, during which the new project is loaded, the wiring is adjusted, and everything is put back into operation.

Our collaboration:

All the required engineering for PLC, wiring, plans and start-up in the factory.

INISA: In your modifications or updates of lines with obsolete electronics

#90