Objetives:

Our client, who is a manufacturer of automatic processing lines for the manufacture of printed circuit boards (PCBs), asks us to collaborate in the engineering of his project, a vertical line to introduce electronic boards into covers/trays with the appropriate chemical component for processing, with final destination to INDIA.

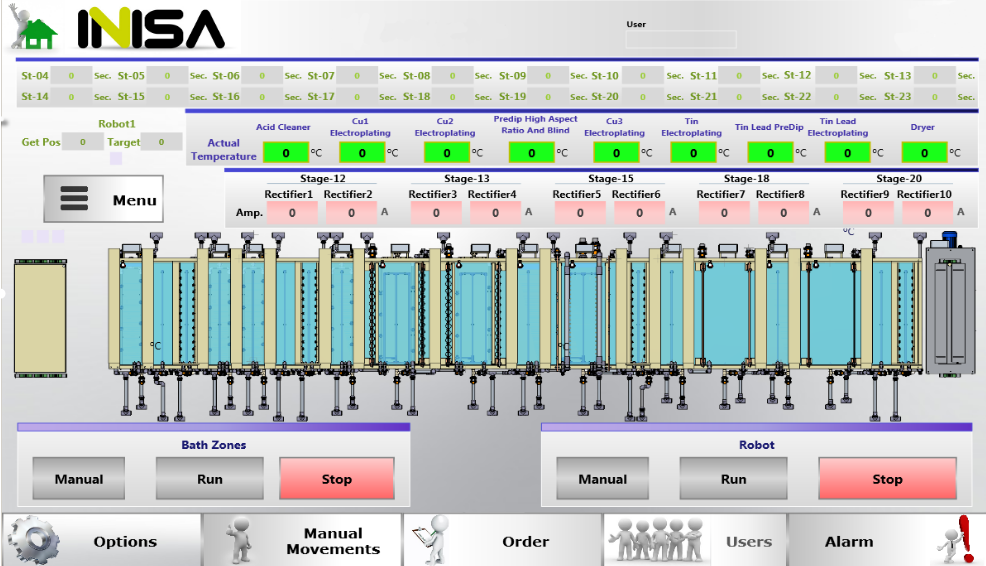

Automation is carried out with OMRON equipment, PLC NX-102-9020, 2 industrial touchscreen PCs, with Soft-NA runtime and OMRON HMI. The line has been tested locally (Spain) and in principle our presence would not be necessary for its installation at destination (INDIA), although our remote assistance is possible (Through EWON equipment).

Process:

The printed circuits are inserted as panels in the different support flybars and are passed through the chemical baths indicated for the contribution of copper, tin or lead, as indicated in the recipe. Each flybar can contain a different finish. Information of times and temperatures is collected during the process, so that at the end of it, generate a report with all its data (Tracking). In the process, rectifiers are used for the electrolysis process with different control modes as required by the process/recipe.

For the movement of the Flybars, there is a bridge controlled in position and speed, which executes the logic and algorithm designed by INISA, optimizing the movements made.

Our collaboration:

- Development of the program in an Omron NX102 PLC using the Sysmac Studio Software, with ETHERNET IP bus.

- Implementation and development of the graphical environment (double screen HMI), using Sysmac Studio.

- Control of CRS Quasar P500 rectifiers (DC, PP, PPR Modes) and control of dispensers according to work recipe, via Ethernet/IP.

- Position control to manage the movement of the crane with the Pepperl&Fuchs WCS3B device and INVT inverters.

- Control of 10 temperature sensors, with trend display and history for the different baths.

- Tracking/Timestamp of process data in recipes.

This collaboration marks the beginning of a series of future projects linked to the printed circuit manufacturing sector, in which INISA contributes its high degree of experience in Industrial Automation.

INISA, your partner in the automation of your lines