Barras que laminándose en continuo entran en unas cajas de laminación a 3 m/s y de las cuales se debe reportar su temperatura máxima de entrada y salida, ser visualizadas en paneles luminosos y ser registradas en BBDD de nivel 2 para su futura trazabilidad y filtrado ? Esta es una automatización sin problemas para INISA, y que nos lleva 2 días de puesta en marcha, incluidos los de test de producción.

Product engineering involve electric plane´s development, component supply and its location in the boxes, PLC and PC programming and SCADA.

We are in charge of the pirometric readers by the configuration and parameterization of a decentralized bus to an existing PLC.

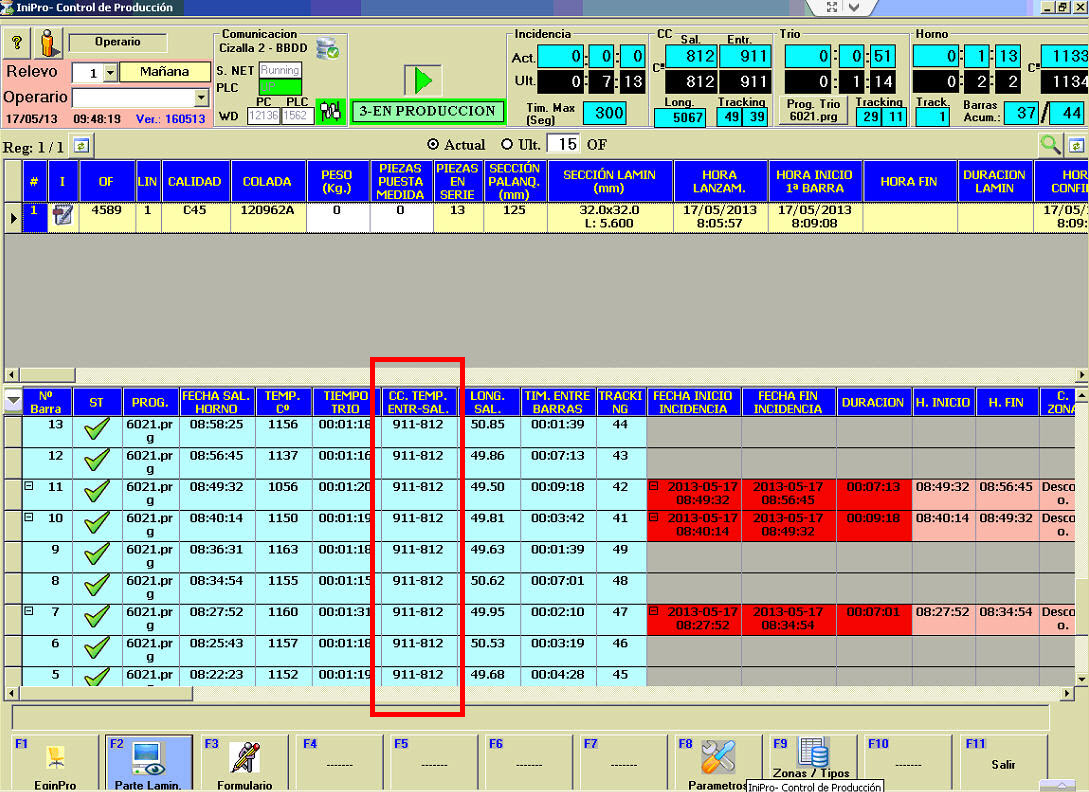

The temperature values are visualized in high contrast panels which can be seed from the distance, and the best is that production staff can visualize on its office computer or remotely longitude values, temperatures, production hours, lamination times, … of each bar putted outside production, 2 seconds after the bar has exit from the last box.

INISA, plant data in any moment and from any place …