Objetive:

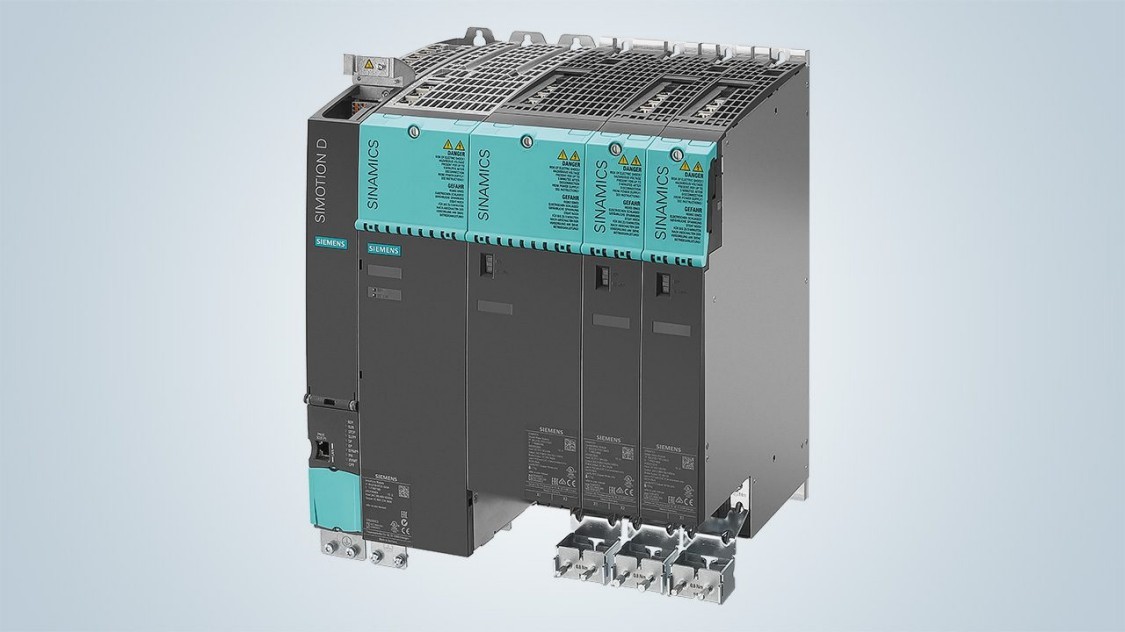

To feed a hot stamping press with the pieces from two heating furnaces using a feeder that has three arms, each one witg three axes (9 axes in total), synchronized to a virtual axis, following a path defined in a flexible way by the operator. For this, we have Siemens Sinamics servos connected via ProfiNet IRT (isochronous real time) network to a Siemens Simotion D455-2 controller.

The result is a feeder of great reliability and repeatability in catching points, trajectory and left, ensuring the quality of the stamping of the pieces, maintaining the necessary cadence. Besides the flexibility that provides the fact that the operator can modify or define new trajectories on demand.

Functionalities, characteristics and ADVANTAGES:

The feeding system has three mechanically independent arms, which synchronize to a trajectory defined by the user.

- The user defines the trajectory with complete liberty, within the mechanical limits of the machine. The path is stored in a recipe associated to a determined product.

- The number of arms to be used is selected by the worker and stored in the recipe. The operator can choose between two or three arms, automatically leaving/taking the unused arm out of the trajectory.

- Once the trajectory is defined, the system verifies it is possible and advises the worker about the conflict points, collisions with the press, path and speed limits, etc.

- The arms have some configurable inputs and outputs depending on the recipe, to allow to hold the piece, verify if it is taken correctly and test if a piece of correct thickness has been taken and there are no two pieces attached. All configurable by the worker.

- It has an automatic calculation of cams for the activation of the digital outputs and the checking of the sensor system. The operator can modify this automatic calculation manually.

- Siemens Simotion D455-2 control and Siemens Simatic servos have the security integrated with the PLC that controls the press by ProfiSafe, allowing safe operation of the machine in any circumstance.

INISA and you, in perfect synchrony