Objectives:

Update the drives of a production line with a PLC, achieving:

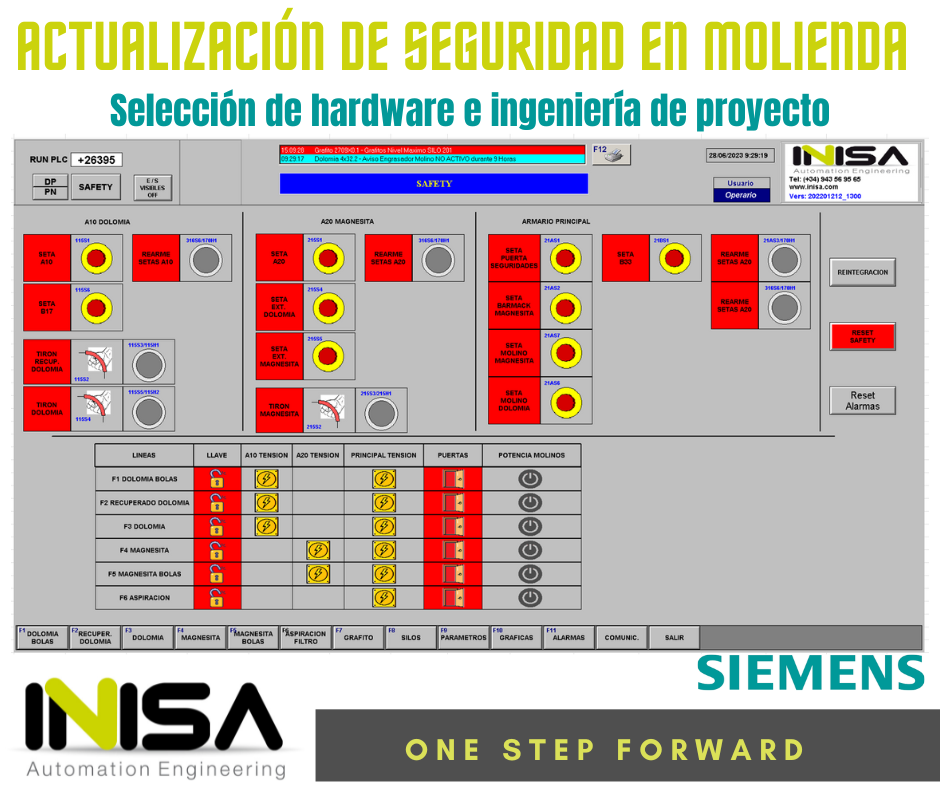

- Unitary and safe control of all emergency mushrooms, pulls, rearmament, sectorization switches, safety relays…

- The production is separated into 6 separate sub-lines, so that maintenance tasks can be performed safely in several of them while the rest remain in operation, avoiding the risks of the maintenance intervention by recording each sub-line (removing the power supply from its drives).

- Make safe stops of all lines, finding safety status information in the SCADA panel.

- Certify the installation by a third (safety certifying organism) in accordance with current safety regulations.

Used tools:

SIEMENS STEP7, decentralised and secure ET200SP inputs and outputs.

Process:

After the analysis of the current equipment and the safety report with the improvement measures, INISA performs the electrical plans for the installation of cabinets, the keypads, the hoses and what is necessary for the project, together with the tune-up at the client’s facilities.

Our collaboration:

Select the hardware equipment needed and perform the Project Engineering.

INISA as Engineering, reliable.