Objetive:

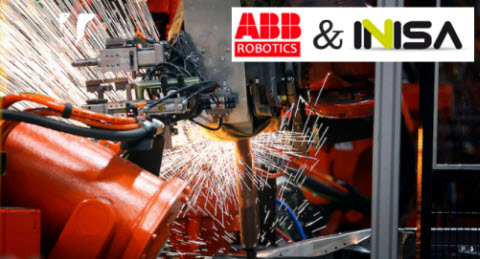

The programming and the commissioning of two cells with 6 robots for welding and handling of car body pieces.

Each cell is provided by 2 robots that carry out the welding in the piece in parallel form. When they finish, the third robot takes the piece, brings it to a static welding place and then it is leaven at the marking station.

This requires to optimize the movements of the robots so that the welding cycle is as efficient as possible, while avoiding collisions between robots in the spaces shared between them.

In this case, INISA is responsible for the development and programming of a total of 6 ABB Robots that are available in the 2 cells.

INISA, also for automations with ABB Robots