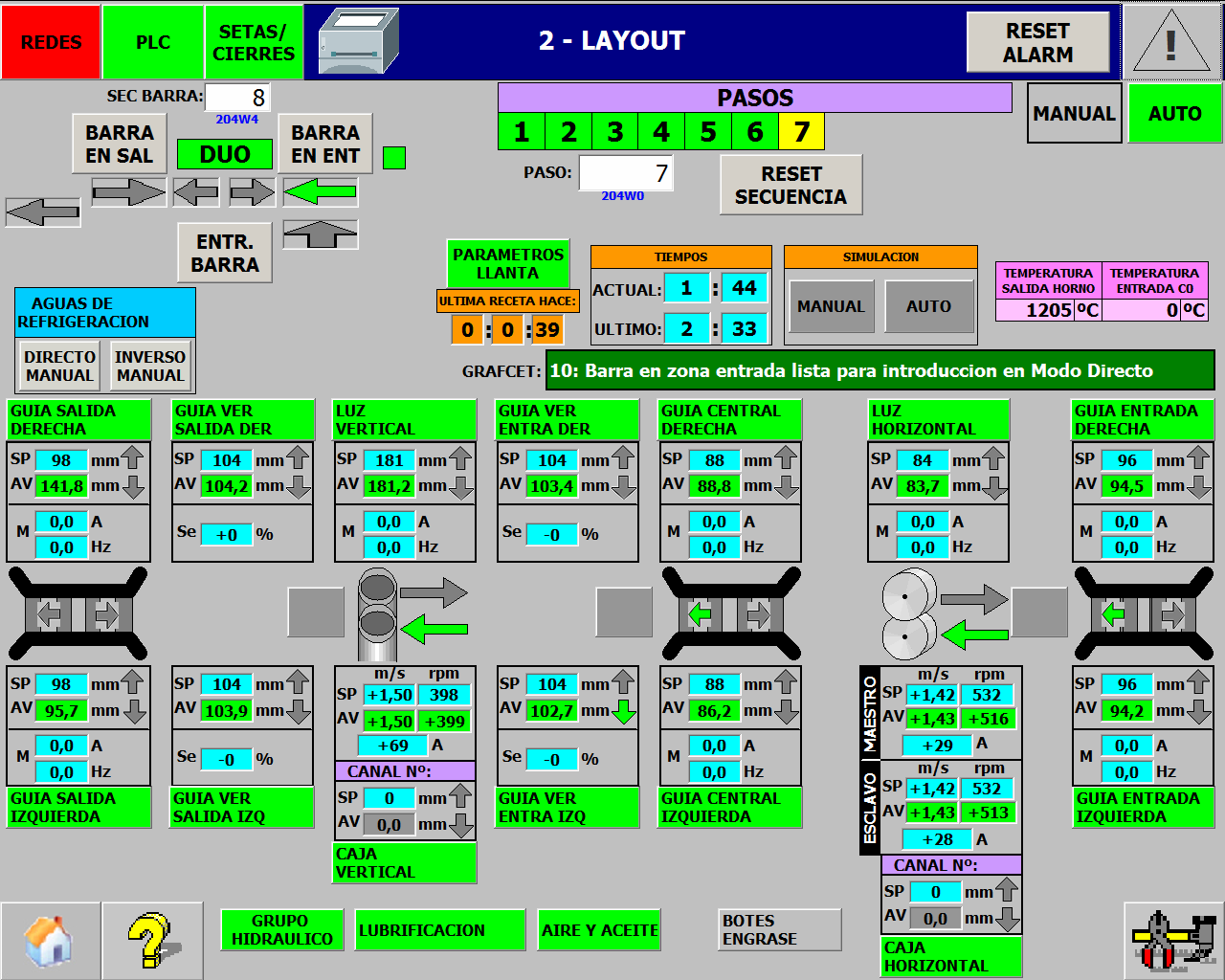

Duo Reversible Boxes Automation

With the process specifications defined by the CUSTOMER, which is a hot rolled product manufacturer, the automation of DUO REVERSIBLE boxes on its installations is undertaken.

Innovative development in the forming of the boxes

The automation demanded changes and tests with a high frequency to adjust with detail al the parameters of the operation, and also on the steps of the GRAFCET`s sequences, required by the process. The modularity and clarity on our programming guarantees a successful delivery to the final customer of the installation.

Cutting saw feeding materials’ sandwich former and its stacking

CUSTOMER: Capital goods manufacturer. MILESTONES:1. To remove the old former and to replace it with a new supply.2. To insert the programming in the current

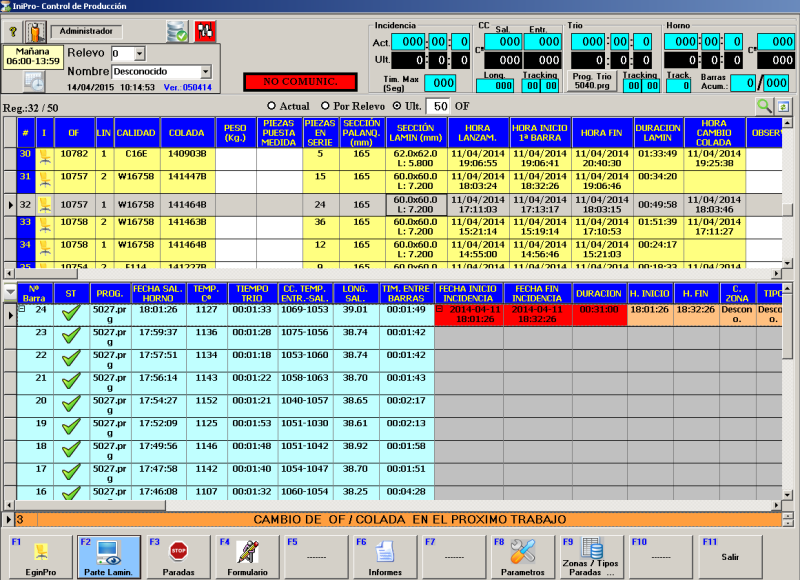

Lamination bars’ temperature’s tracking (Continued Boxes)

To carry out the tracking and the traceability (SQL DATABASE) at billet level, recording furnace output temperatures, input and output to/from continued boxes, as well as the Inter-billet between each of them.

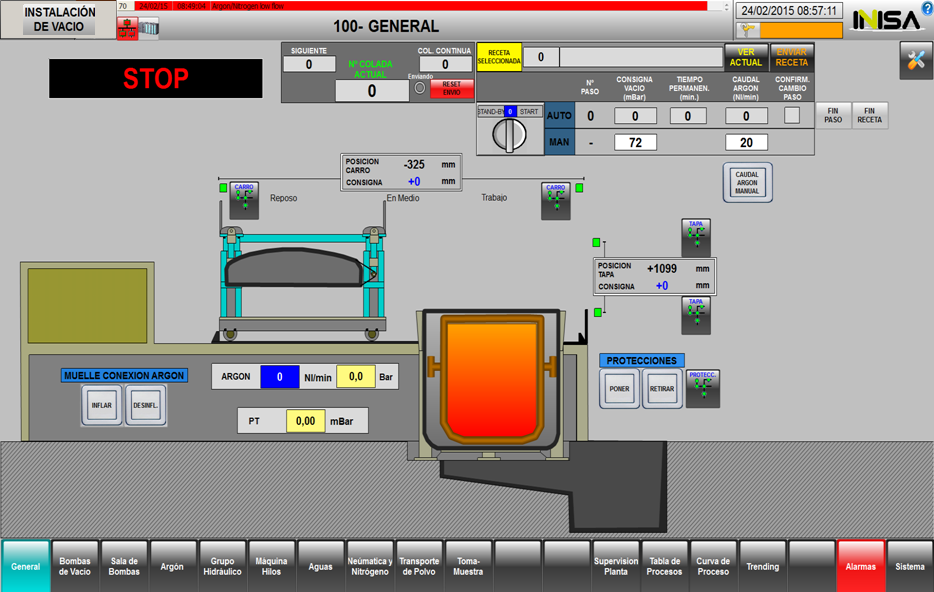

Vacuum degasification system

Steel vacuum degasification appear because of the need to obtain calm steel with low levels of H2, eliminating in this way long thermal treatments and thus avoiding the appearance of flakes or fissures.