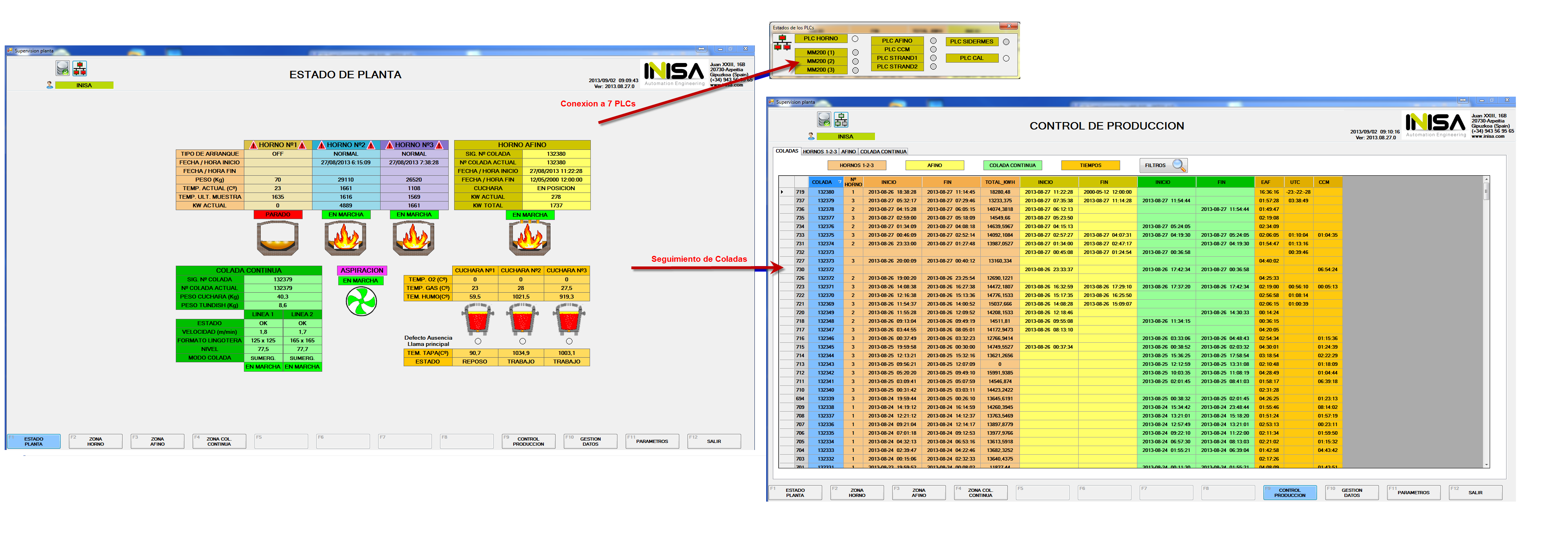

Supervision and record in Data Base, with traceability in a Steel Mill

Fusion furnaces, refining furnaces, continuous casting, refrigeration … processes All of them associated with the castings done in a steel mill and which have to be registered in real time on a Common Data Base for the access from any computer of the plant or from outside…

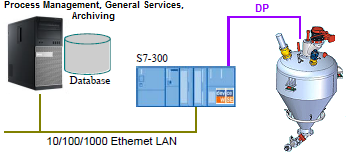

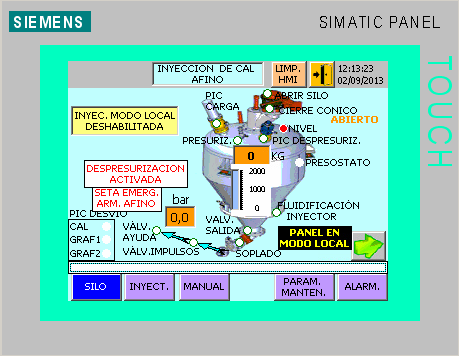

Level 2 lime injection PLC communication

NECESSITY: To know the data about the additives used in lime and additive injection processes. PROBLEM: The process PLC doesn´t have a communication canal with

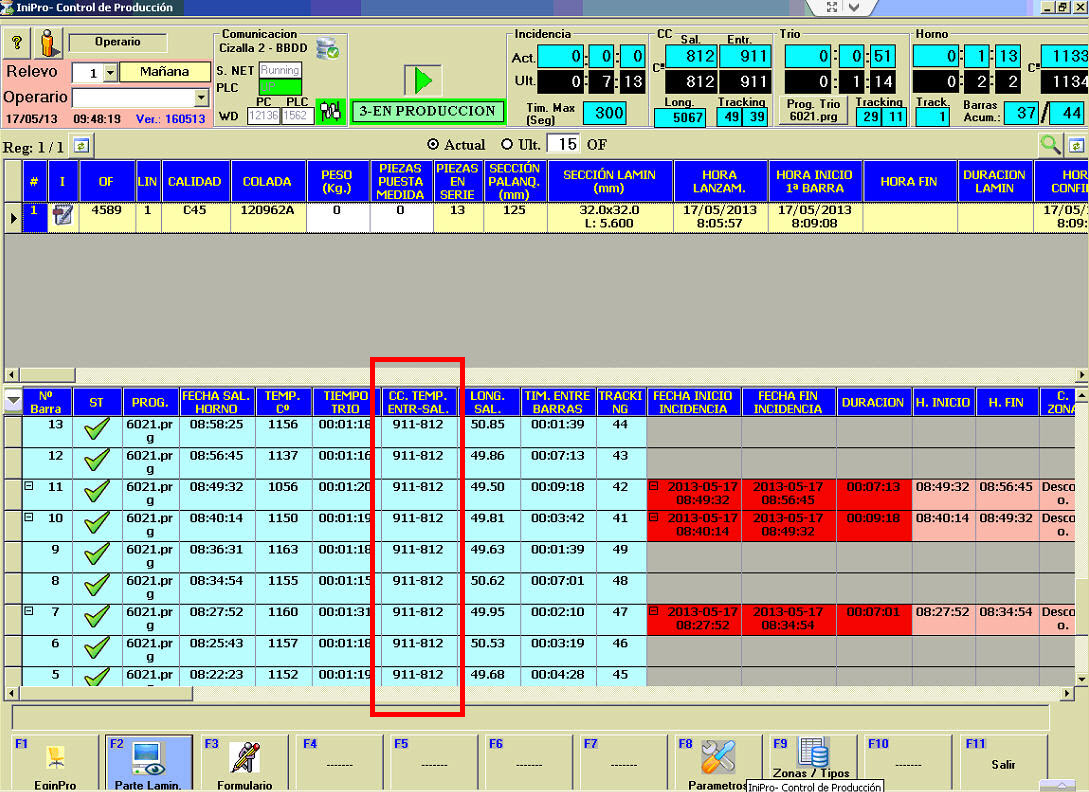

Visualization and record of temperatures in Continuous Boxes of Lamination

Continuously laminating bars which enter in lamination boxes at 3 m/s and whose maximum in and out temperature must be reported, must be visualized in luminous panels and recorded in level 2 Data Base for its future traceability and filtration? This is a smoothly automation for INISA, and which takes us 2 days for its commissioning, including production tests.

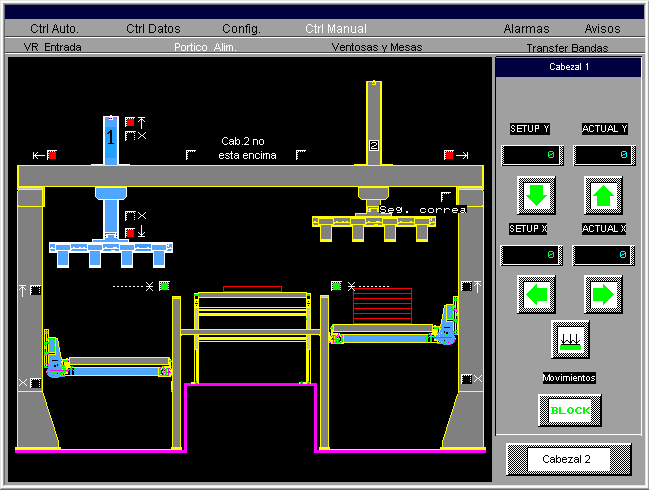

Availability increase of the machine in the double head feed

The automation improvement that our final customer demands consist on allowing the work of a machine with only one head when it is originally designed to work with two heads, and with an optimized sequence of work. Therefore, it is a complex work regarding its PLC programming, but it allows very fast work cycles, in the order of 25 for minute.

Lime injector in an additive installation

It is order to us the programming (PLC and SCADA) and the commissioning of a LIME injection installation, together with the injections of graphite, managed as well as from local posts as from Level 2 computer.