Diagnosis, certification and safety adequacy (Royal Decree 1215/1997) of a press in production

Our client entrust us the adaptation of an existing and operating press, for compliance with the regulation under Royal Decree RD1215, increasing and modernizing the security measures of a press in production.

After the implementation of the measures proposed and validated measures by a competent third party on security, the result is a great reduction of the possibility of accidents and the increment of safety in the use of the press by the operators, maintaining the production and creating safe protocols in work processes.

BOSCH REXROTH servo drives on rotary table in robotic cell

Our customer entrust us the adaptation of a table in the exit of a press, servo driven with a BOSCH REXROTH brand driver, with precise control of the positioning of the reception of the product and its presentation to a palletizing robot. All with optimized and product orientated work dynamic.

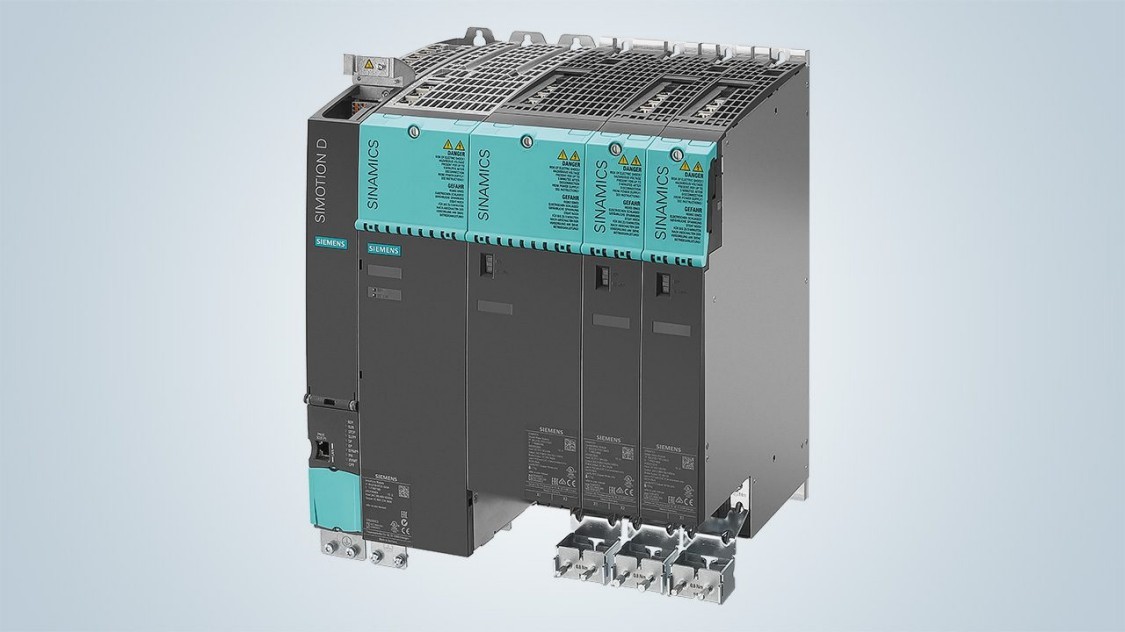

Automotive press feeder with nine synchronized axis (Siemens Simotion D455-2)

To feed a hot stamping press with the pieces from two heating furnaces using a feeder that has three arms, each one witg three axes (9 axes in total), synchronized to a virtual axis, following a path defined in a flexible way by the operator. For this, we have Siemens Sinamics servos connected via ProfiNet IRT (isochronous real time) network to a Siemens Simotion D455-2 controller.

Kuka Robot in a smart palletizing line

Our client, in one of its production facilities, wants to optimize the performance of a Kuka robot for the collection of finished product from a tray and its subsequent palletizing, increasing the number of collected products on each extraction (from 4 to 6 suction pads), and the speed and the functionalities of the palletizing by programming the PLCs, Robot and SCADA.

4.0 Industry: Energy and production management in production facility (Capital Goods Sector)

Our customer, Capital Goods manufacturer, and in a line that is already installed and in production, wants to register and analyse information relative to energetic consumption, reached pieces production and other plant parameters, that allow future decisions for the optimal exploitation. Both, from the point of view of the line manufacturer (Hours of use of the different sub machines, spare parts management, load percentage respect to the nominal, etc.) as well as the point of view of the production/productivity achieved. All this in order to optimize and offer better installations and services to its customers in the future.