Housing/PCB Assembly Line

Our client, a manufacturer of automatic lines for the precise insertion of components in the Automotive sector, asks us to collaborate as Engineering in one of its lines for the introduction of electronic boards into a housing, for the electric car/e-mobility market. The lines are made up of various areas, such as preparation, assembly tables and clinching. INISA is in charge of the development of the HMI software in its entirety, including, in addition to the OPC UA communication with the process PLCS and the SCADA for managing the entire line, communication with the end customer’s traceability system that allows knowing all the production process in it.

INISA AUTOMATION, S.L. official sponsor of AZKOITRI

We are proud to be official sponsors of AZKOITRI, the triathlon team from Azkoitia. We see ourselves reflected in their values, we share their objectives, and we accompany them in their evolution and results. Through them, we think it is a good way to reflect our strengths, and therefore we are lucky to team up with them.

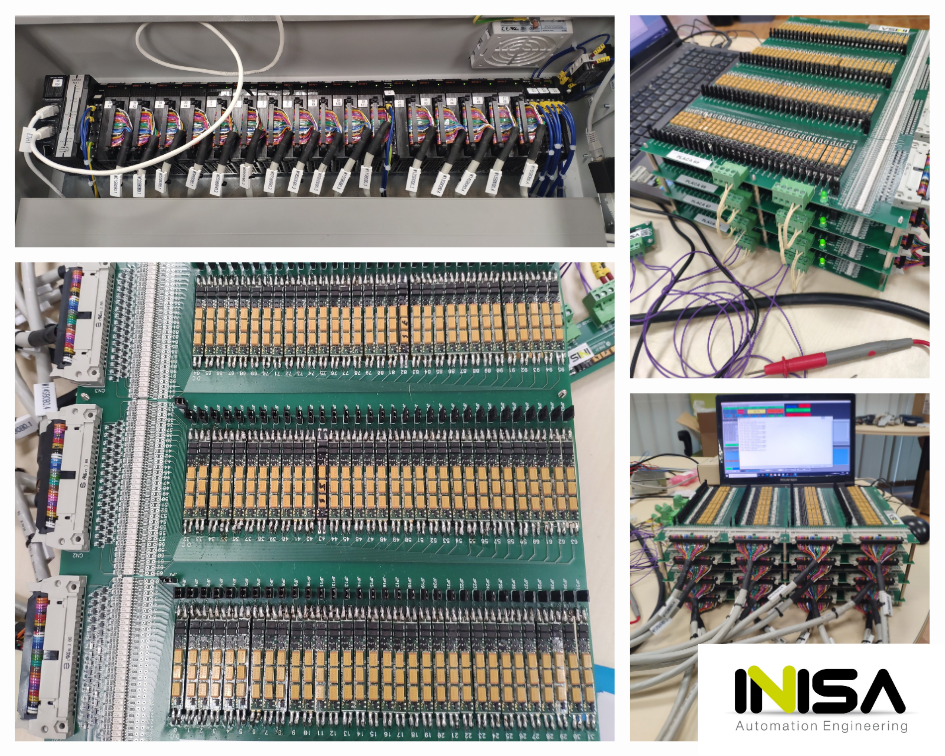

1 millisecond Test Bench expansion and supply of electronic control boards (PCBs)

To carry out the engineering and supply of an extension for a Test Bench already carried out by us previously, to measure the process times of up to 2560 input signals, synchronized to a control signal for the beginning of the Test.

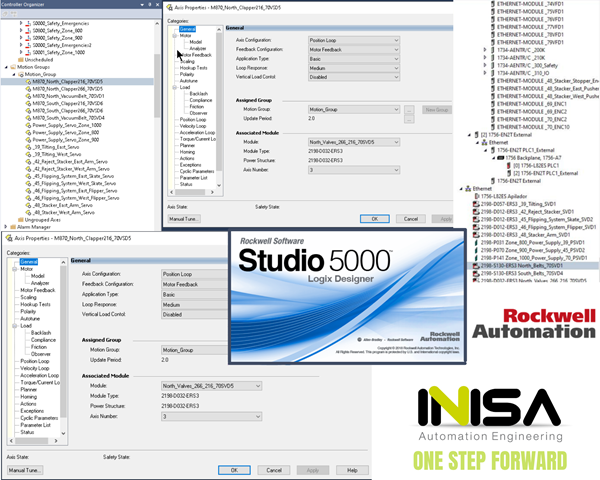

Pneumatic Feeder/Stacker (Rockwell PLC and drives)

Our customer, automatic processing lines manufacturer, asks us to collaborate in the engineering of plasterboard feeding and stacking line, with the programming and commissioning of a part of the installation.

This order is the consequence of the successful execution of a similar project in USA, which significantly increase the client’s productive capacities, and in which we participate by carrying out the programming and the commissioning.

Press line retrofit with intelligent palletizing

Engineering development for the retrofit of press + KUKA palletizing robot installation existing, adapting them by updating the equipment (Security PLC + Profinet communications and decentralized + New Kuka Robot + New HMI), programming all this and generating a new electric project. Carrying out the set-up at the scheduled maintenance shutdown for its installation (2 weeks).