Production data management in a manufacturing plant

What is needed is to identify the necessary and existing production variables in the plcs already in the plant to be able to access to its variables bidirectionally (reading and writing) using a browser, interacting in this way with their information from higher-level systems.

Filling and closing boxes line automation

Our mission is the programming and set-up of a filling boxes line with the necessary pieces to obtain a complete kit, which is later assembled and mounted by the end user who buys it.

Box former automation

Sequence control and up to 13 servos synchronism programming for the realization of cardboard boxes, that by its folding and gluing they can contain products in Kit, filled by another part of the line and using KUKA robots for the automation.

Impregnation deposits automation

This engineering comprises the automated management of several impregnation deposits for its application on continuous impregnation rollers, all in an existing line.

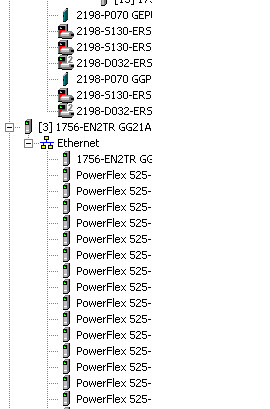

Servo drives? Also with Rockwell PLC

In addition to performing Automation Engineering with the most common PLCs in their latest development versions (Tia Portal, Omron, etc.), INISA provides high specialization services in other platforms, maybe less used in Europe, as Rockwell PLCs, but with more use in the American continent.